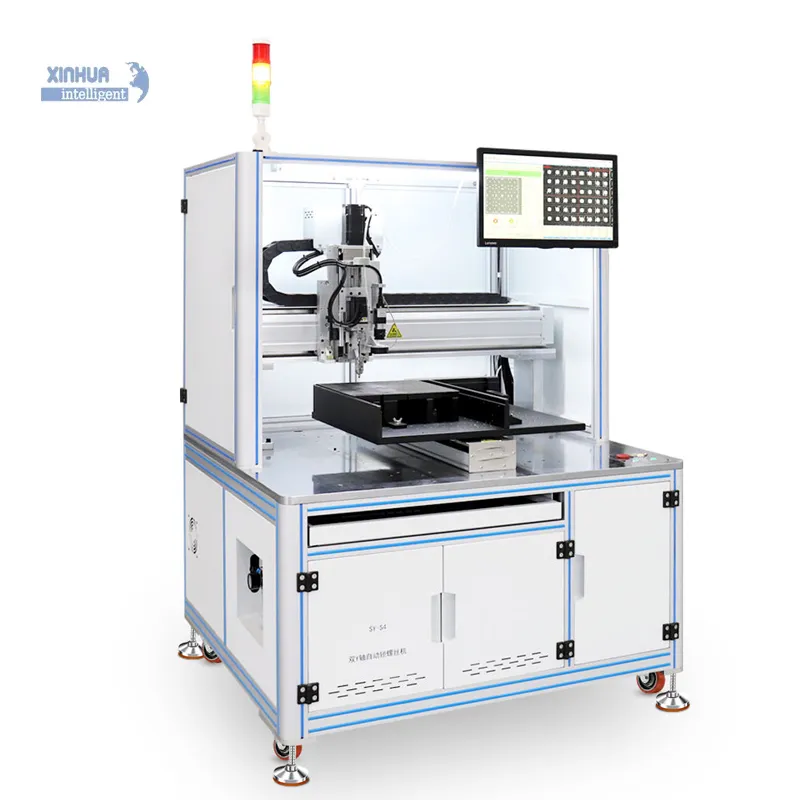

Details:

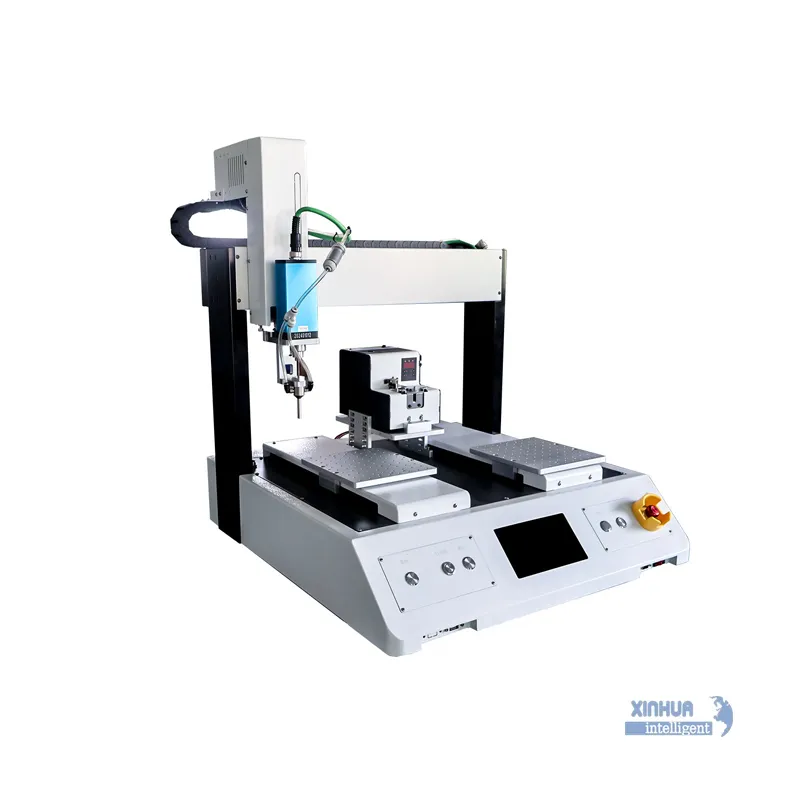

Four-axis dual working stations, Strong Compatibility, Can Work Alternately Left And Right, Double The Efficiency

1. The screw picking method can support vacuum suction or magnetic suction;

2. It can drive stainless steel screws and meson screws (vacuum suction).

3. It supports deep holes, inclined holes, elastic surfaces, and surfaces with different heights (magnetic suction).

4. It supports driving two different screws at the same time (one product), and the intelligent servo electric screwdriver supports three different torques at the same time.

5. It can merge two processes to drive screws (after driving one process, stop, assemble the parts, and then drive another process screw).

6. Intelligent servo electric screwdriver, fast speed, high precision, low noise, long life, maintenance-free: torque (0.3-9KGf.cm), speed (0-3000 rpm), can be set arbitrarily on the touch screen.

7. Rice gold frame, strong rigidity. The height of the feeder can be adjusted freely, supporting products of different heights, and strong compatibility.

8. Closed-loop stepper motor, high precision, position compensation, no step loss.

9. Equipped with self-developed motion control card, fool-style programming, optional drag-style adjustment, easy programming.

10. Equipped with Weiluntong human-machine interface touch screen, dynamic display of lock status, electric screwdriver speed, electric screwdriver torque, real-time monitoring.

11. Four-axis double Y platform, can work alternately, high efficiency.

12.The Automatic Screw Locking Machine supports screw diameters from M0.6 to M4 (mm).